MAG-TURBOWASHER®

The TURBOWASHER® is built to break-up clay containing minerals. Due to its method of working, the material is put under a great deal of stress and material composites, conglomerates and agglomerates are broken up and washed. The main advantage is its relatively low energy and water consumption.

Its construction as a modular system allows individual adjustment to the required solution characteristics. Since wear is mostly limited to the tools and their holders, the wear costs are predictable and economical in relation to the throughput capacity.

- Particle size up to max. 80mm

- 40-80 t/h for poorly soluble material

- 60-100 t/h for medium soluble material

- Drive power 37 kW

Principle of operation

The material is put under pressure and is then crushed through friction. The fine particles are then washed out, which reduces their obstructive lubricating effect. A thick layer forms in the machine, which allows light materials to become loose and float to the surface. The material is continuously mixed which cleans the grain and helps to increase the removal of fine constituents.

How it works

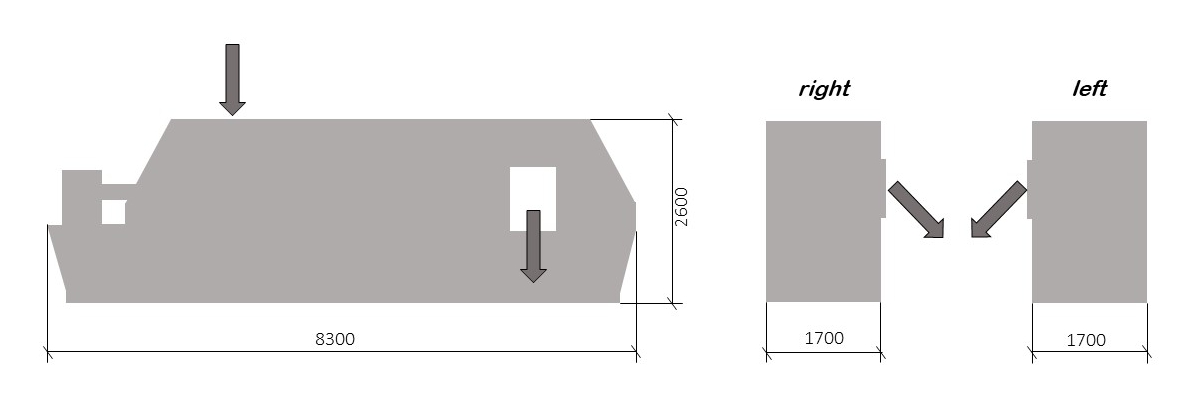

The material is fed into the TURBOWASHER® on the feed side and conveyed through the machine during the washing process. The heart of the machine is the horizontal rotor in the trough. This rotates the tools through the material bed and creates the friction required for washing the material. The number, width and wedge angle of the tools are matched to the material. The filling level as well as the retention time can be controlled by various measures, which has an influence on the washing intensity and flow rate.

As a general rule: It is not possible to get any cleaner and everything else only results in unnecessary wear. Depending on the version, the washed material emerges from the side at the end of the machine. The floating light material is separated on the opposite side. An even more intensive separation of wood and light materials is possible with the additional discharge bucket elevator.

Try for yourself, with a non-binding sample wash of your problem material.

Practical examples of the TURBOWASHER®

Design

The machine has a strong profile frame with a stable trough and is self-supporting. The rotor shaft is of a solid special construction and has flanged shaft journals for the bearing. Thanks to the modular system, the dissolving tools can be individually adjusted at any time to the material which is to be dissolved. A lubricated labyrinth seal is used as a seal and can be replaced on the installed machine. The trough can be emptied for service purposes via hinged and wedge-secured cleaning openings.